The Components and Impacts of BIPV Solar Power Plants

2022-04-15 09:30

PV Building System refers to the installation of PV Power Systems on buildings. According to the different installation methods combined with buildings, it can be divided into Building Integrated PV (BIPV) and Building Attached PV (BAPV) .

Hereby, we will introduce the components and impacts of BIPV solar power plants from the following 10 aspects:

- 1. Solar Panel

- 2. Solar Inverters

- 3. Solar Mount Structures

- 4. PV combiner box

- 5. Cables

- 6. Project Solution

- 7. Installation cost

- 8. Project insurance

- 9. System debugging

- 10. Monitoring system

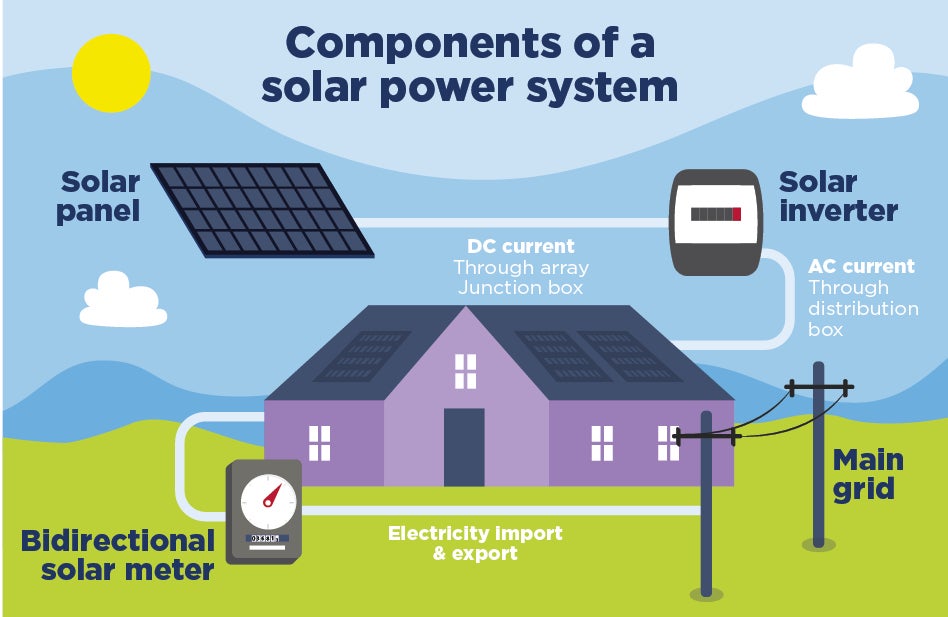

1. Solar Panel

Solar Panels are the core components of PV power plants, whose quality and lifespan are key factors affecting power generation efficiency, and have a direct impact on the benefits of power plants. The costs of solar panels normally account for approximately 50% of a project's total cost. The quality of the solar panels is mainly divided into Class A and Class B. It is recommended to choose a class A product to better ensure a 25-year service life when there is a large-scale project.

2. Solar Inverters

Single/three Phase Solar Inverters.

Inverter is the key equipment for power conversion and grid connection. Choosing a high-quality inverter will make great contributions to maintaining the stability of the photovoltaic power station system.

3. Solar Mount Structures

Solar Mount Structure is a special structure for fixing solar panels and some other related equipment. Its structure and design are generally customized according to each project. The general materials of solar mount structures are carbon steel,stainless steel, magnesium-aluminum-zinc, aluminum alloy and so on. The design of solar mount structure should meet the following requirements:

(1)wind speed and snow load at site; earthquake resistance should also be considered in earthquake-prone areas;

(2) PV layout array should be combined with the local sunshine conditions,

should not be blocked, and strive for more sunshine;

(3) 25-year service life.

4.PV combiner box

Several photovoltaic cells are collected in series and connected to the photovoltaic combiner box. This combiner box has a lightning protection function. The currents of multiple battery strings are combined in the photovoltaic combiner box, output through the DC circuit breaker, and used together with the photovoltaic inverter to form a complete photovoltaic power generation system, which can be connected to the grid.

5.Cables

DC cables are generally installed outdoors and require sun protection, cold protection, moisture protection, and UV protection. Therefore, for DC cables in photovoltaic systems, we generally select photovoltaic certified professional cables.

6.Project Solution

It includes grid-connected access design and PV power station design. The rationality of the project design not only affects the construction cost of the power station, but also extremely affects the power generation efficiency. It is normally designed and optimized from the following aspects:

(1) The rationality of the arrangement of photovoltaic support components, avoiding occlusion, and striving for sufficient sunlight;

(2) The way of grid connection;

(3) Electrical access design.

7.Installation cost

The labor cost of EPC installation is affected by the complexity of the project, as well as the wage level of the installation area and some other factors. If the budget permits, we suggest you to order a high pre-assembled solution with easier & quicker installation.

8. Project insurance

It includes construction personnel insurance and project operation insurance. The price of insurance is affected by the content and scale of the insurance.

9.System debugging

It should be completed by grid employee or professional trainer to test the stability of the photovoltaic system.

10.Monitoring system

It can control and monitor the combiner boxes, inverters, battery arrays, sun tracking control systems, AC and DC power distribution cabinets and other equipment in the solar PV power station, and output the data and charts accordingly for engineers to grasp the operation of the power station quickly. Meanwhile, when there is an alarm or failure occurs, engineers can analyze the cause in time and try to repair it as soon as possible to reduce losses.

Power Stone is a professional solar mount structures manufacturer with an annual production capacity of 2GW and is still expanding to efficiently fulfill the orders from customers overall the world. Focusing on quality, professionalism and innovation, we always provide customers with the best PV project solutions. Power Stone looks forward to becoming your most reliable partner in solar energy industry.